Let us tell you the “hole” story

1993

In 1993, Paul Ameloot, managing director of the lighting design and manufacturing company DeltaLight, developed the original large hole frame system, known as DMK. It’s original function? To hang DeltaLight’s light fixtures. This first generation of frames was made with steel; far too heavy to be used practically. To combat this issue, Paul Ameloot decided to switch to aluminum frames. The DMK frame system offered many advantages over the track light profile system that was common at the time.

With these new frames, users no longer had to assemble profiles one by one saving huge amounts of time.

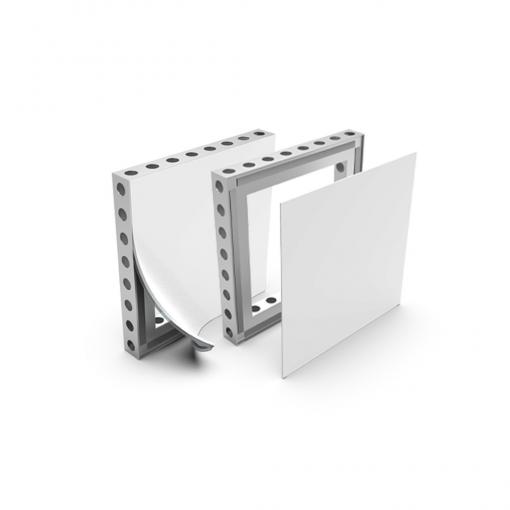

With frames, hard panel or fabric infills are placed in front of the frame giving you a custom look while hiding the aluminum. By hiding the structure, cosmetic scratches to the frames themselves don't compromise the booth's design.

Our ECO frames are welded, making them lighter and stronger than assembled frames. Once they've completed their lifecycle and are ready to be disposed of, our frames are completely recyclable due to their 100% aluminum construction.

2004

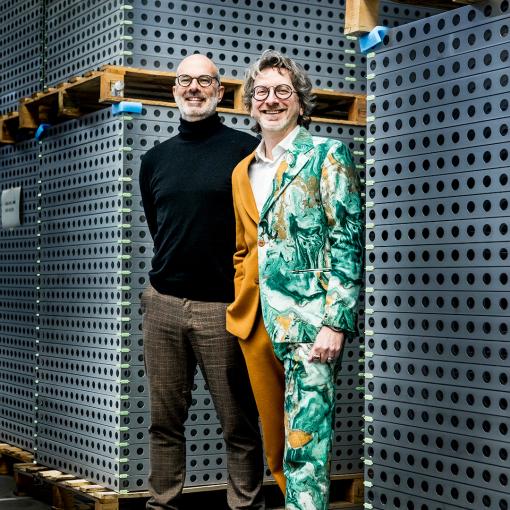

Due to the explosive growth of DeltaMatrix (the frames and profiles department of DeltaLight), it was becoming difficult to give DeltaMatrix the focus it needed to grow. As a result, Paul Ameloot started looking for partners to further develop and market the growing frame system. Stefaan Decroos and Edwin Van der Vennet became those partners by buying DeltaMatrix in 2004 and founding beMatrix that same year.

From its headquarters in Roeselare, Belgium, beMatrix has grown from a general unknown entity to a market leader in just 19 years. Our strategy is built on five key principles: be the best - be the first - be everywhere - be together - be sustainable. We take this strategy into account for all our decisions, both strategic and day-to-day. Read more about the beMatrix strategy.

2007

As time went on, textile infills became a high demand finishing option. beMatrix adapted to this market demand by developing an additional type of frame with slots to accommodate textiles. That made for two separate kinds of frames: one for infills and one for textiles.

2012

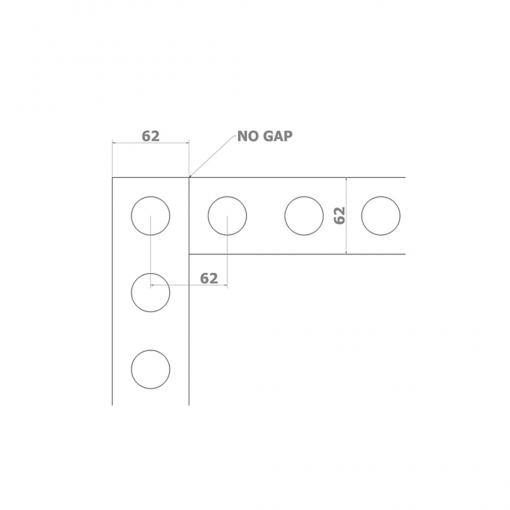

2012 was the year when the panel frame and the textile frame became one, with one catch: the frames were 62 mm instead of the previous 55 mm. This was the start of the well-known and award-winning b62 frame.

The change from 55 mm to 62 mm proved popular. When making a corner by pinning together two 55 mm frames, there would always be a gap of 3.5 mm. With the introduction of b62, the gap disappears, and the frames fit together seamlessly. Additionally, 55 mm frames require flat connectors and square pins so as to not interfere with SEG fabric. Our solution? The 62 mm beMatric frame.

The b62 frame system won the coveted Red Dot Design Award in 2013! The Red Dot Design Award is internationally recognized as one of the most prestigious quality-based awards for good design. Thus, begun the technological boom for beMatrix with many additional products coming to market, including the 360° solution, LEDskin®, ECO pins, special-customized frames, etc. These innovations ensured that the b62 frame system could be used for nearly any construction.

2019

Beginning January 1st, 2019, beMatrix began offering frames with an ECO+ finish. This new finish was a big leap forward in our push towards sustainability. ECO+ used a new brushing technique that replaced the environmentally damaging anodization. Click here to read more about our sustainability efforts.

In addition to changing up the finish with ECO+, we also introduced a thinner type of Velcro hook and loop tape. This new Velcro has become the standard when producing beMatrix frames and allow for panels to fit deeper inside, providing a better finish for the customer.

2023

beMatrix has evolved countless times over the years, and so has our team. From what was once a small team has grown into an organization of more than 180 beManiacs. You never know, you might be the help we need to build an even brighter future for our frames! Learn all about the beMatrix DNA.

Cheers, to another 30 more years of b62!