What

CircuMatrix is the sustainable reconversion of our production hall, which is built with the same or other recycled materials. CircuMatrix is split into different phases so that our production remains uninterrupted.

Circular + beMatrix = CircuMatrix

Why

It's beMatrix’s ambition to produce fully energy neutral by 2026. CircuMatrix is essential to obtain our climate and growing objectives. No effots or expenses are spared to make this happen.

Where

We are staying in our hometown Roeselare: right in the exact same place! beMatrix HQ is located in the industrial zone ‘Beveren-Wijnendale’ in Roeselare, West-Flanders. We have three sites. Site 1 was reconverted back in 2012. Now it’s time for site 2 and 3. Both sites will melt together to one big production site of 9575 m²!

When

The preparations for CircuMatrix started in 2023. The project is progressing in several phases over 2024 and 2025.

In 2023, we finalised the project preparations and secured all necessary permits. Together with our architect, we spent a lot of time researching how we could reuse the demolished materials.

At the beginning of 2024 we started building the new production hall. We decided to build higher to get 1000% more storage space! Doing so, we’ve recuperated as much demolished material as possible. To give a few examples:

- The existing asphalt pavement was milled on site so that it could be directly reused as a foundation for the production hall.

- All crushed stone used to lay the new paving is 100% recycled material.

- All excavated soil was stabilised with lime to ensure sufficient bearing capacity.

Writing this – it's the beginning of 2025 and we are in the middle of renewing what we call site 3. This is the place where you pick up your orders!

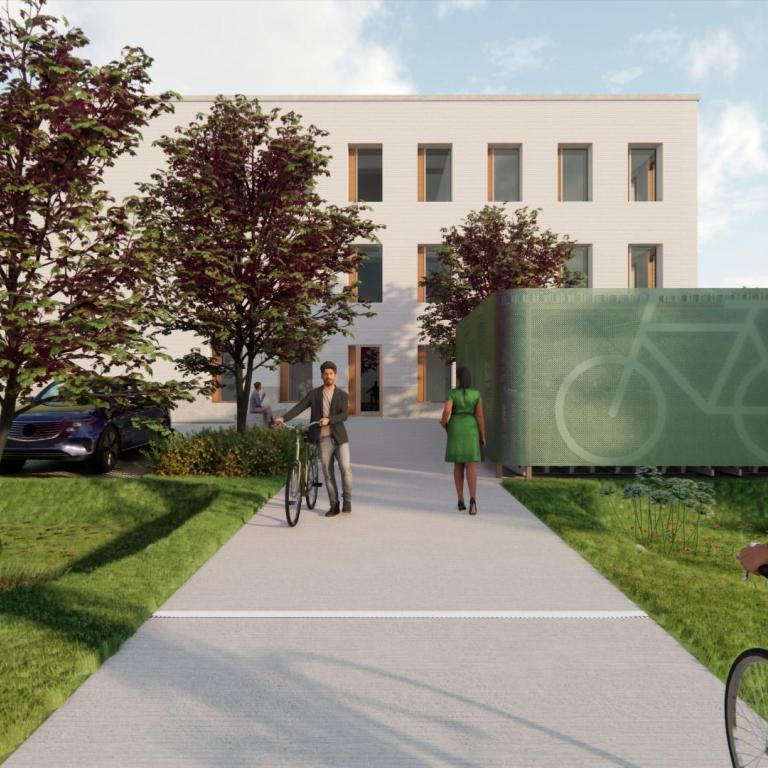

Next to the production, packing and logistics hall – of course the offices can’t be forgotten. The new offices will be oriented facing a green area. For an energy-efficient and comfortable working place, geothermal heating and cooling will be installed complemented by a flexible, acoustically and thermally insulated interior.

The star of the show will be the unique façade of the new building, constructed from the aerated concrete panels of the demolished production hall. These panels were carefully dismantled and sawn on site to form building blocks for the new façade. By stacking the 15 cm thick panels horizontally to create a 60 cm thick façade, we will achieve an exceptional insulation value. Of course, we examined this thoroughly with experts in the field. The test rig showed its simplicity in execution and high-quality stability.

At last, the car park will be rearranged and equipped with spacious bicycle parking (with charging stations) as well as smart charging stations for our 100% electric vehicle fleet.