Let us tell you the hole story

1993

In 1993, Paul Ameloot, managing director of DeltaLight - a Belgian family-owned lighting design and manufacturing company - developed the original large hole frame system, DMK. These structures were needed to hang their light fixtures. The very first generation of frames was in steel. The weight of the steel frames was an issue, so Paul Ameloot soon decided to switch to aluminium frames. The frame system had many advantages over the trench profile systems common at the time. We list them briefly below:

With frames, you don't have to assemble profile by profile on-site. You start immediately with a frame, which saves a huge amount of time.

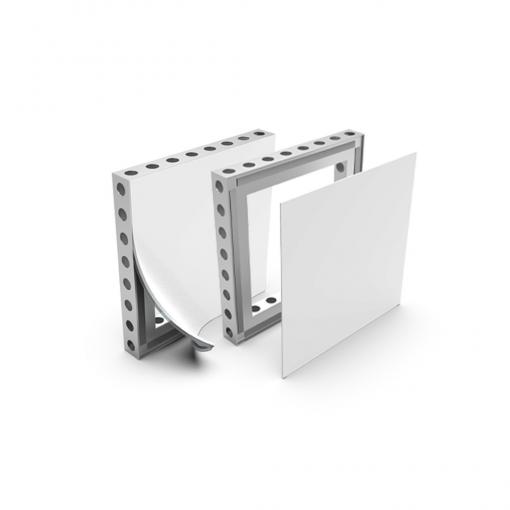

With frames, the panel (which is only 3 mm thick) or fabric is in front of the aluminium and not in between. The aluminium structure is hidden behind the graphic, as it were, which looks a lot nicer aesthetically. An additional advantage is that the structure can last much longer because scratches remain invisible.

All frames are also welded, which makes them lighter and stronger than assembled frames and at the end of the life cycle, you have a product that consists 100% of aluminium and is therefore perfectly recyclable.

2004

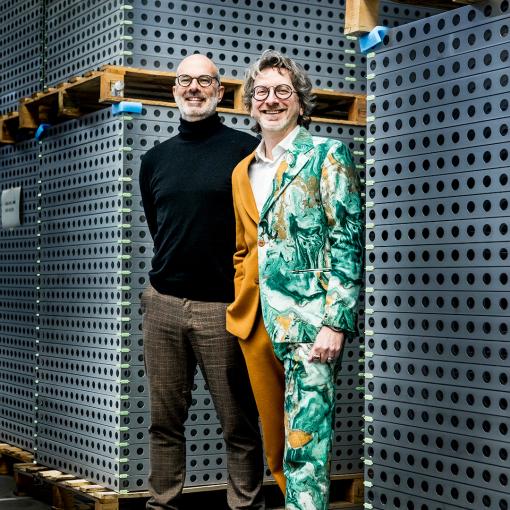

Due to the extreme growth of DeltaLight, the frames and profiles department, DeltaMatrix, was not getting the focus it needed and Paul Ameloot started looking for partners to further develop and market the frame system. Stefaan Decroos and Edwin Van der Vennet bought the original frame system in 2004 and founded beMatrix in the same year.

From its headquarters in Roeselare (BE), beMatrix has grown from a noble unknown to market leader in 19 years. Our strategy is built on five principles: be the best - be the first - be everywhere - be together - be sustainable. We take this strategy into account when making both strategic and day-to-day decisions. Read more about our strategy.

2007

From the retail sector, textiles are coming on strong as an infill, so beMatrix developed a second type of frame with slots. So currently, we had a separate frame for panels and a separate frame for textiles.

2012

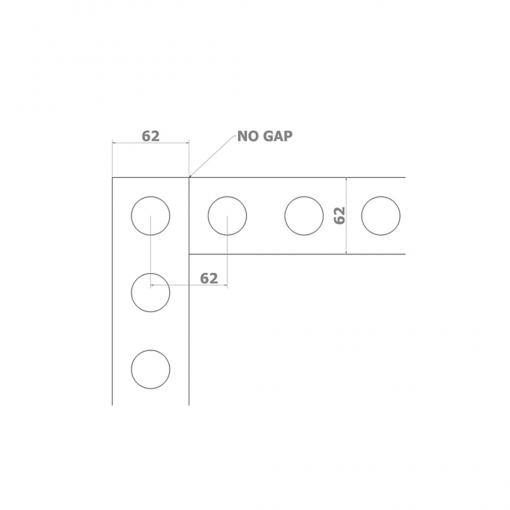

2012 was the year when both frames (for panel and textile) merged into 1 frame, although with a different width, 62 mm instead of the former 55 mm. This resulted in the well-known and award-winning b62 frame.

The evolution from 55 to 62 proved to be a hit. If you make a corner with a pin and a 55 frame, you always keep seeing a gap of 3.5 mm. With b62, you don't have this and the frames fit together seamlessly. On top of that, with a 55 frame filled with panels, you can see the notches very well. Finally, a 55 frame requires flat connectors and square pins to not interfere with the SEG textile. Our conclusion? The 62 matrix offers the best result.

Our innovation, the b62 frame, was awarded as a Red Dot Design winner in 2013! The Red Dot Design award is internationally known as one of the most desirable quality seals for good design. During this period, beMatrix came onto the market with all kinds of additional products such as the 360° solution, LEDskin®, ECO pins, special customised frames, etc. These additions ensured that the frame could be used for just about any construction and more and more stand builders started using it.

2019

From 1 January 2019, beMatrix offers frames with an ECO+ finish. A big leap forward in our sustainability story. This brushing technique in the production process is to replace the highly environmentally damaging anodising of aluminium. Click here if you want to read more about the ECO+ finish.

Alongside the entry of the ECO+ finish on the frames, a new type of Velcro was also introduced, which from then on is the standard within beMatrix. We opted for a thinner version allowing the panels to fit even more inside the frame, so that we can guarantee the customer a better finish.

2023

So the aluminium frame with big holes has evolved a lot over the years, and so has our team. A small team that you could count on two hands has since grown to more than 180 beManiacs. Maybe it's something for you to help build the future of the frame? Find out all about the beMatrix DNA.

b62, we'll add at least 30 more years!