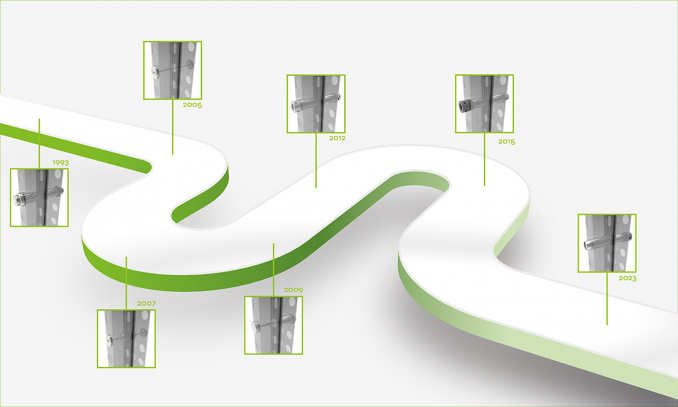

1993: Chromed Tube

At DeltaMatrix, the frames were connected using a chromed tube D30 and 2 tension rings. The chromed tube was pushed through the holes of the frames and a ring was fitted at both ends that connected the frames.

However, it was noted that the frames could no longer come apart but were not stuck together either. In addition, you needed a small hex key to screw those little screws in and out. Each bolt thickness needs a different number of hex key, so you needed a whole arsenal of tools that had to be taken to an exhibition build-up each time. This process took up a lot of assembly time and also all the tools took up a lot of space that could be put to better use.

2005: Clamp Connector

To securely connect the frames together without movement, we brought out the Clamp Connector D30. This was a long M6 bolt with 2 nut plates on each side. Only 1 screw needed to be tightened with an Allen key which sped up the process.

The frames were now nicely attached to each other with no play, but they were definitely not aligned opposite each other. This left too much play possible which did not make construction easy. A new task for our R&D department to work on!

2007: Double Clamp Connector

To address slack, a new intermediate tube was fitted at the new connector that ensured frames were levelled against each other. In other words, the frames hung tight to each other without slack and were leveled.

The connector was crowned the Double Clamp Connector D30 ANO. Again, you had to tighten the clamp on one side with an Allen key.

2009: BIG INNOVATION: Toolless Connector

We want our system to be simple and easy to use, so any mixed or complex connections are out of bounds. We needed a connector that is usable without any tool for quick mounting and a stable construction. The Toolless connector was born.

We launched the first beMatrix connector in 2009 that you can assemble without tools. In other words, with a simple twist of the clamp, you attach your frames to each other. This great innovation allows for much faster assembly & disassembly and also no more lugging around extra equipment.

The Toolless Connector or at the time Manual Double Clamp Connector D30 ANO, provided connection, pulling the frames together and horizontal levelling of the frames and all this with a connector that could be mounted without tools.

Moreover, this connector could be used for all beMatrix frames. This " toolless" connector has therefore become a fixture within beMatrix. We still work with it, subject to some slight modifications.

2012: Toolless Connector D30

In 2015, the current Toolless Connector D30 entered the market. Simple, user-friendly and durable were the keywords. The clamp became even more user-friendly with its tapered shape and large screw head made of aluminium.

This clamp is very strong and can now also be used for large and outdoor constructions. It is a durable product with a very long life cycle, lightweight, without surface treatment and therefore 100% recyclable.

2015: The Toolless connector 2.0

The aluminium end you used to screw the clamp on started to clamp due to the expansion of the aluminium. The clamp also became a bit heavy because of this. We switched to the current plastic head, made of POM (Polyacetal) to prevent expansion and lower the weight.

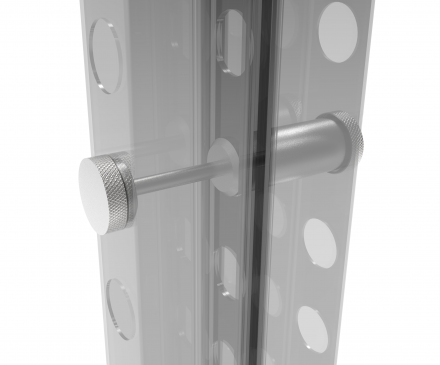

2023: The Fast Clamp (patent pending)

The Fast Clamp is the successor of the Toolless clamp, the 7th of its generation. Fast Clamp allows an even faster, easier, stronger and more sustainable toolless connection between two aluminum frames.

No more screwing! Thanks to the push button on one side activates an ingenious locking mechanism. The Fast Clamp can be left in its position during transport and storage. Last but not least, stock management will be simplified because it remains one piece. No individual parts can get lost or separated from each other.