We are living in a world of continuous change. Our R&D team therefore works daily on product and process optimisation while always bearing the ecological footprint in mind.

The ECO frame was launched a few years ago as an ecological alternative to the anodised frame. Anodising is an additional step in the production process in which the frames are given an extra layer. Since this chemical treatment is detrimental to the environment and, what’s more, is unnecessary for indoor use, beMatrix then decided to offer ECO frames.

ECO+ Finish: a cleaner look

In order to be able to rival the level of finishing of the anodised frame, we are now adding an extra surface treatment in the production process. This involves a brushing technique, which does no damage whatsoever to the environment and results in ECO frames that look almost identical to anodised frames.

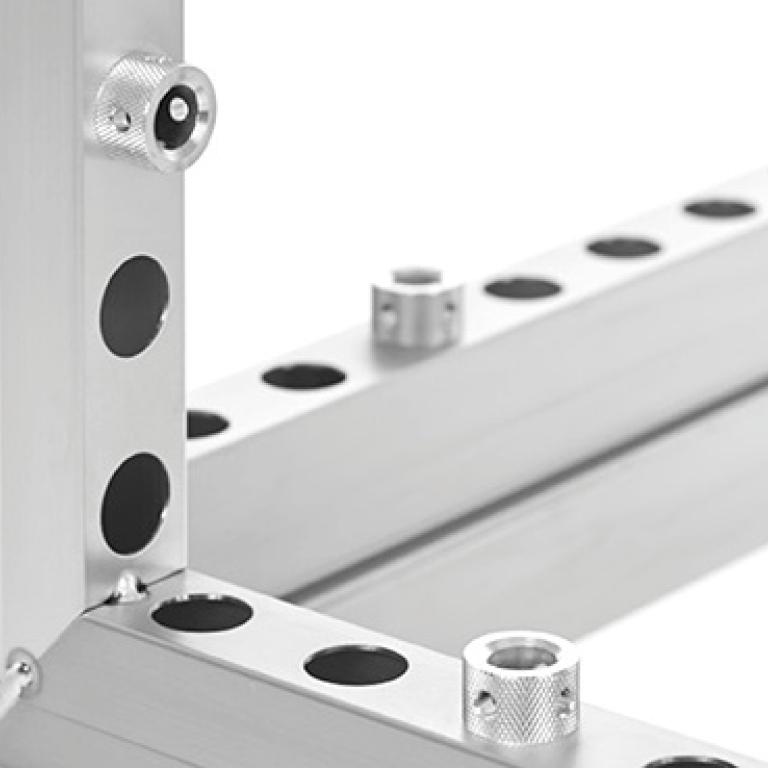

The new frames are fully compatible with the existing frames.

Design Optimization

For years now, beMatrix has opted for welded frames because of their strength properties. As a result, the bracket slot became redundant and has consequently been removed in the new design, making the frame lighter and thus more ergonomic for the user.

New type of hook and loop tape

This durable surface treatment also goes hand in hand with the application of a new type of hook and loop tape which, as extensive tests have proven to us, surpasses the quality of the current hook & loop. After all, when it comes to arches & ceiling applications, proper adhesion is certainly a must.

We opted for a thinner version, which means that panels fall even more within the frame, so that we can guarantee you a better finish. This new type of Hook and loop tape is becoming the worldwide standard within beMatrix and is compatible with existing panels having the current type of hook and loop tape.

All frames ordered from 1 January 2019 will be delivered with this new surface treatment and hook and loop tape.

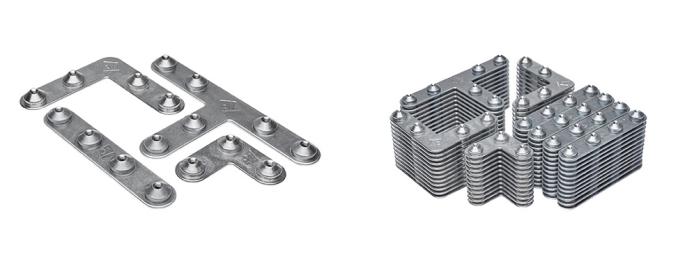

ECO-pins

From 1 January, we are also introducing a new range of ECO-pins, with which the frames are attached to each other at top and bottom. Since recently, these are no longer being chromium plated, but are manufactured in a Zamak alloy (an acronym for Zinc, Aluminium, Magnesium and Copper). The environmental impact of this treatment is much smaller than the treatment with chromium: it reduces carbon emissions by up to an eighth and halves the weight of the pins.

In addition, due to its design, the new pins will be fully stackable, in turn giving you more space during storage and transport.